At GxP Central, we help FDA regulated businesses navigate the regulations process for the manufacture of new drugs and medical devices. Our FDA Consultants provide clients with unequaled guidance on all aspects of regulatory compliance with decades of experience in manufacturing, quality control, clinical trials, packaging/labeling, and compliance audits. Don’t risk your company’s future by ignoring or minimizing the challenges of regulatory compliance. Contact our team today for an initial consultation.

GxP Central places a premium on the importance of continuous compliance monitoring to ensure that your efforts are both current and effective. Our consultants possess extensive domestic (US) and global experience and can cover the entire supply chain from raw materials to finished products.

Audits of Sites, Suppliers, and Supporting laboratories

SOPs are written processes that describe in detail how to perform a work task-specific to your operations. Documenting standards properly allows businesses to comply with regulatory and quality standards, train more effectively, and enable a culture of continuous improvement. GxP Central provides

Areas of expertise across drugs, biologics, devices, diagnostics, nutraceuticals, dietary supplements, food, combo products, compounding pharmacies, and radio-pharma include:

Clinical—21 CFR Parts 50, 54, 56, 312, 314, 361, 14155

Manufacturing—21 CFR Parts 210, 211, 111, 820, 600, 601, 610

Non-Clinical—21 CFR Part 58

Electronic Records/Signatures—21 CFR Part 11

ISO—13485, 14155, 14971, 22716, 9000s, 62304, 15189, 17025

ICH—Q7A, E6, E2A

Compounding Pharmacy—USP 797

European Directives—2001/20/EC, 2005/28/EC

Canadian Medical Device Regulations— SOR-98-282

Pharmaceutical manufacturers are required to carry out audits of their suppliers or have audits conducted on their behalf by appropriately qualified, experienced auditors. A GMP audit is a mission-critical component in the regulatory process that enables pharmaceutical manufacturers to meet the predetermined FDA compliance standards.

GxP Central frequently performs good manufacturing practice audits globally at a number of supplier sites to ensure GMP compliance. We carry out Full Site audits that focus on the facility’s quality management systems and cover a large number of products.

Pharmaceuticals/Biologics: Our approach to cGMP quality system implementation for biologic and pharmaceutical manufacturers (21 CFR Part 210 and 211) complies with FDA’s Compliance Program 7356.02.-A System Based Inspection of Drugs and focuses on the proper implementation and sustainability between the following six systems:

Design of Quality Systems for:

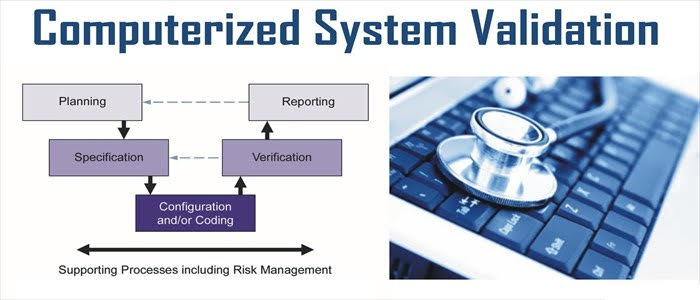

We work with our clients to develop scalable resource plans to support validation efforts throughout the project lifecycle. Whether it is drafting protocols to execution and compilation of data packs, our resources have you covered.

Validation Master Plans (VMPs)

Operational Qualification (OQ)

Our services are punctuated by superior quality standards, attention to detail, transparency , and longstanding relationships with our clients. We are committed to conducting work in a transparent manner to ensure that activities are always ethical without any conflict of interest.